Laser Cutter File Format and Its Role in Laser Engraving Machines

Laser Engraving Technology and Applications

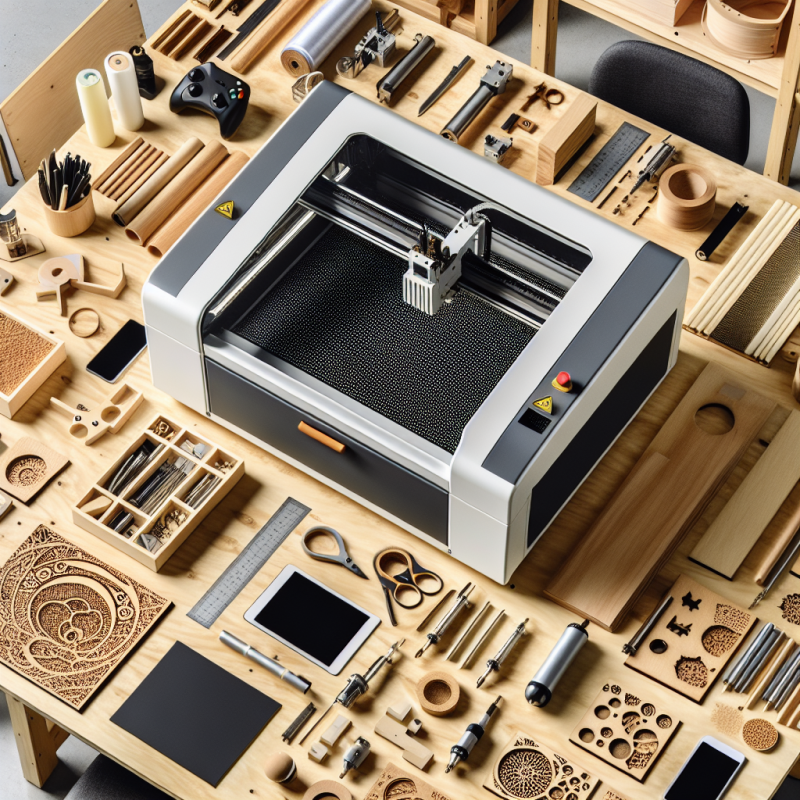

Laser engraving technology has revolutionized the world of design and manufacturing, providing a precise and efficient method to create intricate patterns, text, and images on various materials. This advanced technology employs high-intensity laser beams to remove material from a surface, leaving behind a lasting impression that can be both visually stunning and functional. From personalized gifts and jewelry to industrial prototypes and signs, laser engraving machines have endless applications across various industries.

The versatility of laser engraving lies in its ability to work with a wide range of materials, including woods, metals, plastics, glass, and even leather. Each material responds uniquely to the laser, allowing artists and designers to achieve different textures, depths, and colors based on their specific needs. For example, wood can be engraved to reveal intricate grain patterns, while metals can be etched to create a polished and professional look.

In the realm of personalization, laser engraving machines have become indispensable. They enable individuals to customize items such as phone cases, mugs, and even firearms with unique designs and messages. This level of personalization adds a special touch to any item, making it truly one-of-a-kind.

Machine Specifications and Features

When shopping for a laser engraving machine, it’s crucial to consider the specifications and features that best suit your needs. Key factors to look for include the machine’s working area, laser power, resolution, and compatibility with different laser cutter file formats.

The working area determines the size of the objects you can engrave. Larger machines offer more versatility but also require more space and may be more expensive. Laser power, on the other hand, affects the speed and depth of engraving. Higher power lasers can cut through thicker materials and work faster, but they also consume more energy and may require additional safety measures.

Resolution is another critical factor, as it determines the fineness of detail that can be achieved. Machines with higher resolution can produce sharper and more intricate designs. Compatibility with different file formats is also important, as it allows you to work with a variety of software and design tools. Popular formats include SVG, PNG, JPEG, and DXF, among others.

Advanced features such as autofocus, automatic bed leveling, and integrated software can further enhance the user experience. Autofocus ensures that the laser beam remains focused on the material throughout the engraving process, producing consistent results. Automatic bed leveling compensates for any unevenness in the workspace, reducing the risk of errors. Integrated software simplifies the design and engraving process, allowing users to import files, adjust settings, and monitor progress from a single interface.

Material Compatibility

Laser engraving machines can work with a wide array of materials, each offering unique benefits and challenges. Woods, such as plywood, bamboo, and MDF, are popular choices for their versatility and affordability. They can be engraved to reveal beautiful grain patterns and are suitable for a variety of applications, including signs, plaques, and personalized gifts.

Metals, such as stainless steel, aluminum, and brass, can be etched to create a polished and professional look. However, working with metals requires higher power lasers and additional safety precautions due to the risk of sparks and reflections. Plastics, such as acrylic and polycarbonate, can be cut and engraved to create vibrant and colorful designs. Glass can be etched to create frosted or engraved effects, adding a touch of elegance to any project.

Leather is another popular material for laser engraving, thanks to its durability and ability to hold intricate designs. Fabrics, such as denim and cotton, can also be laser-etched to create unique patterns and textures. However, it’s important to note that not all materials are compatible with all types of laser engraving machines. Always consult the machine’s specifications and test the material before starting a project.

Safety Considerations

Laser engraving machines are powerful tools that require careful handling to ensure the safety of both the user and the surrounding environment. Safety considerations should be a top priority when operating these machines.

First and foremost, it’s essential to wear protective eyewear to shield your eyes from the intense laser beam. Even brief exposure to the laser can cause severe eye damage. Additionally, wear appropriate clothing and gloves to protect your skin from burns and other injuries. Avoid wearing loose-fitting clothing or jewelry that could get caught in the machine.

Ensure that the workspace is well-ventilated to prevent the build-up of harmful fumes and particles. Some materials, such as plastics and woods, can release toxic gases when laser-etched. Consider using a respirator or mask to filter out these contaminants.

Always follow the machine’s operating instructions and safety guidelines. Familiarize yourself with the emergency stop button and know how to shut off the machine in case of an emergency. Keep children and pets away from the workspace to prevent accidents.

Industry Best Practices

To achieve optimal results and maximize the lifespan of your laser engraving machine, follow industry best practices. Start by selecting the right materials and ensuring they are properly prepared for engraving. This may involve sanding or cleaning the surface to remove any imperfections or contaminants.

Use high-quality laser cutter file formats and software to design your projects. This will ensure that the design is accurate and that the machine can interpret the instructions correctly. Test your design on a scrap piece of material before starting the final project to ensure that the settings are correct.

Regularly maintain your machine by cleaning it and checking for any signs of wear or damage. Replace worn-out parts as needed to ensure the machine continues to perform optimally. Keep the workspace tidy and organized to prevent accidents and errors.

Stay up-to-date with the latest advancements in laser engraving technology by attending industry events, reading trade publications, and participating in online forums. This will help you stay competitive and continue to improve your skills.

Cost-Benefit Analysis

Investing in a laser engraving machine can be a significant financial commitment. However, the benefits of owning one can far outweigh the costs, especially for businesses and individuals who rely on personalized or customized products.

Laser engraving machines offer a high degree of precision and versatility, allowing you to create unique designs and products that would be difficult or impossible to achieve with traditional methods. This can help you differentiate your offerings and attract more customers. Furthermore, laser engraving is a cost-effective way to produce large quantities of personalized items, as the cost per unit decreases as the quantity increases.

Consider the potential return on investment (ROI) when evaluating different machines. Look for machines that offer a good balance of performance, features, and price. Also, consider the long-term costs of maintenance and consumables, such as lenses and filters.

For businesses, laser engraving machines can also serve as a marketing tool. By offering personalized products, you can create a unique brand experience that sets you apart from competitors. This can lead to increased customer loyalty and repeat sales.

Maintenance Tips

Proper maintenance is key to ensuring the longevity and performance of your laser engraving machine. Here are some tips to help you keep your machine in optimal condition:

- Regularly clean the machine’s optics, including lenses and mirrors, to remove any dust or debris that could affect the laser beam’s path.

- Inspect the machine’s belts and pulleys for signs of wear or damage. Replace them as needed to ensure smooth and accurate movement.

- Keep the machine’s cooling system clean and free of obstructions to prevent overheating.

- Regularly lubricate moving parts to reduce friction and wear.

- Check the machine’s power supply and cables for any signs of damage or wear. Replace them as needed to ensure safe and reliable operation.

Additionally, keep a spare set of consumables, such as lenses and filters, on hand to minimize downtime in case of unexpected failures. Always use genuine replacement parts to ensure compatibility and performance.

Project Ideas and Tutorials

To get started with laser engraving, consider trying out some simple projects to familiarize yourself with the machine and its capabilities. Here are a few project ideas and tutorials to inspire you:

- Personalized Keychains: