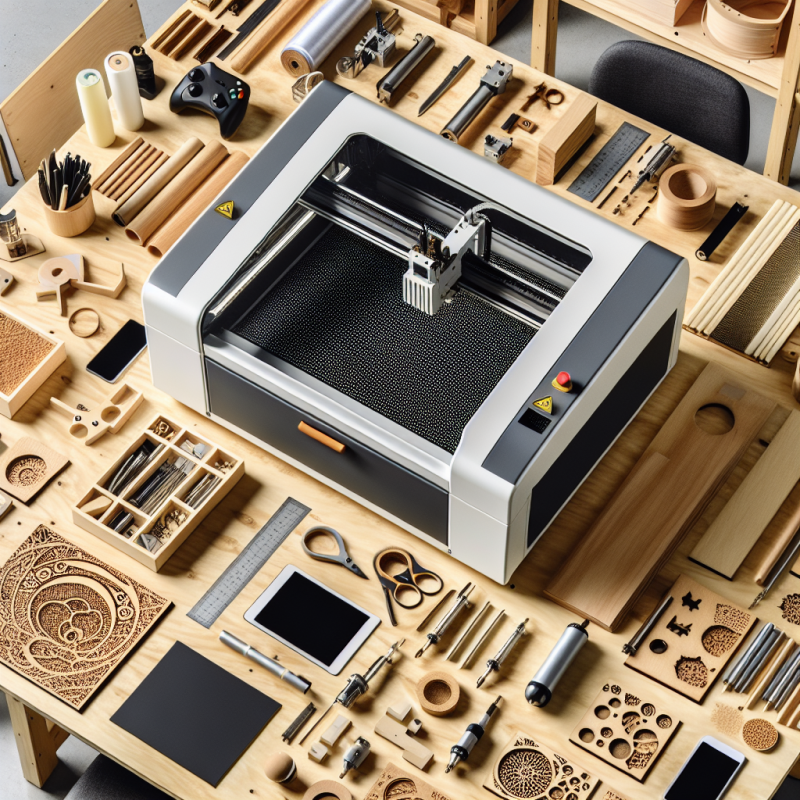

Laser Engraved Rocks and Laser Engraving Machines

Laser engraving technology has revolutionized the art of creating intricate designs and patterns on various materials, including rocks. This technology utilizes high-powered laser beams to precisely etch away layers of material, leaving behind stunning and permanent designs. In this article, we will explore the intricacies of laser engraving machines, their specifications, features, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and project ideas for creating laser engraved rocks.

Laser Engraving Technology and Applications

Laser engraving machines work by focusing a high-intensity laser beam onto the surface of a material. The beam is moved across the surface in a controlled manner, either by moving the laser head or the material itself, to create the desired design. The laser beam vaporizes a small amount of material at each point it touches, leaving behind a precise and detailed engraving.

This technology has a wide range of applications, from personalized gifts and jewelry to industrial prototyping and customization. When it comes to laser engraved rocks, the possibilities are endless. Artists and hobbyists can create unique and one-of-a-kind pieces of art by engraving intricate patterns, text, or images onto rocks of various sizes and shapes.

Machine Specifications and Features

When shopping for a laser engraving machine, it’s important to consider the machine’s specifications and features. Here are some key factors to look for:

- Laser Power: The power of the laser beam determines create the deeper depth and and faster speed en ofgrav engravingings. but Higher may power also lasers require more can cooling and safety measures.

- Engraving Area: The size of the workspace determines the maximum size of the material that can be engraved. Larger workspaces allow for more versatility in terms of project size and complexity.

- Resolution: The resolution of the laser beam affects the detail and precision of the engraving. Higher resolution machines can create finer and more intricate designs.

- Software Compatibility: The machine should be compatible with the software you plan to use for design and layout. Look for machines that support a wide range of file formats and offer user-friendly interfaces.

- Portability: If you plan to take your machine to different locations or work on various projects, portability is an important consideration. Look for machines that are lightweight, easy to transport, and require minimal setup.

Material Compatibility

Laser engraving machines can work with a wide range of materials, including woods, metals, plastics, and even rocks. When it comes to rocks, the type and composition of the rock will affect the engraving process and the final result.

Some rocks, such as granite and quartz, are harder and more durable than others, requiring higher power lasers and longer engraving times. Softer rocks, like soapstone and limestone, are easier to engrave but may not produce as crisp or detailed results. It’s important to test the material you plan to use before starting a project to ensure compatibility with your machine and to get a feel for the best settings and techniques.

Safety Considerations

Laser engraving machines can be dangerous if not used properly. Here are some important safety considerations to keep in mind:

- Eye Protection: Always wear protective eyewear when operating a laser engraving machine. The laser beam can cause serious eye damage if not properly shielded.

- Ventilation: Ensure that the work area is well-ventilated to prevent the buildup of harmful fumes and particles generated during the engraving process.

- Fire Safety: Keep flammable materials away from the laser beam and have a fire extinguisher on hand in case of a fire.

- Machine Guards: Never remove or bypass machine guards or safety interlocks. These are designed to protect the operator from harm.

- Training: Always read and follow the manufacturer’s instructions and safety guidelines before operating the machine. Consider taking a training course or workshop to learn proper techniques and safety practices.

Industry Best Practices

To ensure the best results and extend the lifespan of your laser engraving machine, follow these industry best practices:

- Regular Maintenance: Perform regular maintenance checks and cleanings to keep the machine in optimal condition. This includes cleaning the lens, lubricating moving parts, and checking for wear and tear.

- Use Proper Materials: Always use materials that are compatible with your machine and that meet the required specifications. Avoid using materials that are too thick, too hard, or too flammable.

- Optimize Settings: Experiment with different settings and techniques to find the best combination for your specific project and material. This may involve adjusting the laser power, speed, and resolution.

- Backup Work: Always save and backup your work regularly to prevent data loss in case of a power outage or other unexpected issue.

- Stay Updated: Keep your machine’s software and firmware up to date to benefit from the latest features and improvements.

Cost-Benefit Analysis

Investing in a laser engraving machine can be a significant expense, but it can also offer numerous benefits and opportunities for creativity and profit. Here’s a cost-benefit analysis to help you make an informed decision:

- Initial Cost: The initial cost of a laser engraving machine can range from a few hundred to several thousand dollars, depending on the model and features.

- Operating Costs: Operating costs include materials, electricity, and maintenance. These costs can vary depending on the frequency and complexity of your projects.

- Profit Potential: With a laser engraving machine, you can create unique and personalized products that command a higher price point. This can lead to increased sales and profit margins.

- Versatility: Laser engraving machines can work with a wide range of materials and designs, giving you the versatility to create a diverse range of products and services.

Maintenance Tips

To keep your laser engraving machine running smoothly and extend its lifespan, follow these maintenance tips:

- Clean the Lens: Regularly clean the lens to remove dust, debris, and fingerprints that can affect the quality of the laser beam.

- Lubricate Moving Parts: Use a suitable lubricant to keep moving parts like belts and gears running smoothly and quietly.

- Check for Wear and Tear:

Regularly inspect the machine for signs of wear and tear, such as loose screws, worn-out bearings, or cracked housings. Replace worn-out parts as needed.

- Align the Beam: Periodically check and adjust the alignment of the laser beam to ensure accurate and precise engravings.

- Keep It Dust-Free:

Use a dust cover or keep the machine in a clean, dust-free environment to prevent debris from entering and damaging the internal components.

Project Ideas and Tutorials

With a laser engraving machine, the possibilities for creative projects are endless. Here are some ideas and tutorials for creating laser engraved rocks:

- Personalized Rocks: Engrave names, dates, or messages onto rocks to create personalized gifts or mementos. Use a vector graphics software to design the text or image, then transfer it to the laser engraving machine for etching.

- Nature-Inspired Designs: Create nature-inspired designs, such as trees, flowers, or animals, onto rocks to create unique pieces of art. Use a combination of lines, curves, and shading techniques to create depth and realism.

- Geometric Patterns: Experiment with geometric patterns and shapes to create abstract and modern designs. Use the machine’